Nanotechnology Can Increase Buildings’ Energy Efficiency

Directory 2013

Increasing numbers of existing industrial buildings are being renovated to reduce energy costs by using new nanotechnology-based coatings. (Nanoparticles in these coatings are one billionth to one millionth of a meter in size.) These coatings make it possible to reduce energy bills without major construction costs. Companies owning older buildings and firms seeking to buy or lease these buildings can realize substantial reductions in operating costs, thereby making these older buildings more valuable assets.

The primary location of heat loss is usually through windows. Buildings constructed in the 1940s and 1950s, especially in the northern United States, present the greatest challenge in this regard. Many of these older buildings include multiple rows of single-pane windows, as well as solid block wall construction that is difficult to insulate with traditional materials. Replacing 40,000 square feet of windows can be cost-prohibitive, even though it means savings down the road. With this in mind, many older manufacturing buildings are being successfully renovated and reopened using nanocoatings on their windows.

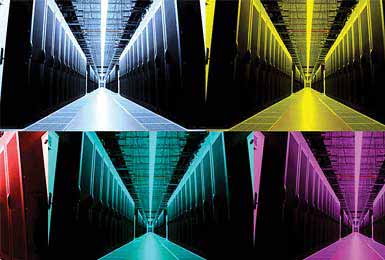

For example, General Electric opened a new $48 million data center in one of the original buildings in its sprawling Applianc

e Park complex in Louisville. “Increased amounts of energy consumption in data centers have become an industry-wide issue,” says Riccardo Rutili, general manager of GE’s Digital Energy business. The renovations in this 1950s era building addressed this issue. The building is one of the few data centers to have received Platinum LEED certification. An important reason for this is the nanocoatings used on the building windows.

Insulated Window Coatings

While there are many potential benefits to be gained from manipulation of materials at the nanoscale level, nanocoatings have been one of the first to make it to the marketplace, helping companies reduce energy costs. For example, Industrial Nanotech, Inc. (Naples, Fla.) began operations in 2004. Its Nansulate® line of coating products has been used worldwide. The coatings incorporate a nanotechnology-based material with very low thermal conductivity. This clear, paint-on insulating coating can be used to reduce heat conduction as well as provide resistance to moisture, corrosion, mold growth, and ultraviolet (UV) rays. In most cases the nanocoatings are applied as a liquid using standard paint application equipment, and are fairly invisible over most surfaces, except glass. However, painting over old windows is substantially cheaper than installing new, well-insulated windows. Painted on windows or skylights, the coating will give a slightly frosted look and allow through visible light while reducing heat loss and UV penetration. Thermal energy transmission can be reduced by nearly 35 percent at a product cost of 50 to 59 cents per square foot.

A benefit of using coatings is the flexibility to apply them over an entire building at once or to divide the building into zones with the coating being applied to one zone at a time. The building owner can focus on the highest energy-savings zones first and later use the energy savings to pay for applying coatings to other parts of the building. These savings can provide the manufacturer with an economic advantage over competitors.

Project Announcements

P.C. Campana Plans Vicksburg, Mississippi, Production Operations

12/25/2025

Midwest Equipment Manufacturing Expands Maysville, Kentucky, Operations

12/25/2025

Stord Expands Hebron, Kentucky, Warehouse Operations

12/25/2025

Edelweiss Dairy Expands Freedom, New York, Operations

12/24/2025

Hut 8 Plans West Feliciana, Louisiana, Data Center Operations

12/24/2025

Coley Home Expands Claremont, North Carolina, Manufacturing Operations

12/24/2025

Most Read

-

The Workforce Bottleneck in America’s Manufacturing Revival

Q4 2025

-

Rethinking Local Governments Through Consolidation and Choice

Q3 2025

-

Lead with Facts, Land the Deal

Q3 2025

-

Investors Seek Shelter in Food-Focused Real Estate

Q3 2025

-

Tariff Shockwaves Hit the Industrial Sector

Q4 2025

-

America’s Aerospace Reboot

Q3 2025

-

The Permit Puzzle and the Path to Groundbreaking

Q3 2025