For more than 130 years, the timber industry has been a major driver of Arkansas’ economy. In recent years, the industry has enjoyed somewhat of a renaissance.

Arkansas’ forestland consists of approximately 19 million acres, covering more than half of the state. Because of responsible stewardship of the land, forests in Arkansas have more trees and are healthier than the forests of more than 100 years ago.

“We understand the forest,” says Arkansas Gov. Asa Hutchinson. “It’s not a new phenomenon here.”

Max Braswell, executive director of the Arkansas Forestry Association, says it makes a difference when 83 percent of the forestland is privately owned, because private landowners rely on the forest for their livelihood. “Foresters are the original green guys,” said Braswell. “It’s not just a catch phrase; it’s a way of life for regular people who on a daily basis commit their lives to doing the right things on the landscape.”

An Abundant Supply

That growth and care for the land has created one of the best timber baskets in the country and, perhaps, the world. Hardwoods, such as oak and hickory, account for 41 percent of the timber in the state, while pine is responsible for 31 percent of the cover. We have an abundance of supply. But we also have the capability of getting those forest products into the marketplace with the major east-west and north-south interstate networks and our modern rail systems. Arkansas Governor Asa Hutchinson “We have an abundance of supply,” Gov. Hutchinson said. “But we also have the capability of getting those forest products into the marketplace with the major east-west and north-south interstate networks and our modern rail systems.”

The supply and proximity to major consumer markets makes Arkansas an attractive place to do business. For example, Conifex, a Canadian-based forestry services company, recently announced that it purchased an abandoned mill in El Dorado in south Arkansas and will soon be producing lumber products. A friendly corporate tax rate system and a recently reduced income tax rate, along with business affordability, are reasons the company cited for expanding into Arkansas.

“We selected this location because we will have affordable delivery costs to important lumber consuming markets such as Texas, Florida, and the East Coast states,” said Ken Shields, CEO of Conifex. “There is both a strong forest products culture here and a good workforce.”

Arkansas forestry and wood products, however, are exported all over the world. Australia, Mexico, and Spain are Arkansas’ major trading partners for forestry products such as timber and logs. Canada, Mexico, and China are the top three destinations for sawmill and wood products. And Canada, Mexico, and Japan receive a bulk of the paper products produced in the state.

Arkansas' Booming Timber Industry

Arkansas has nearly 19 million acres of productive timberland, covering more than 50 percent of the state.

-

Georgia-Pacific

Crossett, ARGeorgia-Pacific operates one of the world’s largest forest-products complexes in Crossett, which is located in deep south Arkansas.

-

Conifex

El Dorado, ARConifex, a Canadian-based forestry services company, recently announced that it purchased an abandoned mill in El Dorado in south Arkansas and will soon be producing lumber products.

-

Domtar

Ashdown, ARBob Grygotis, general manager of Domtar in Ashdown, says the workforce is changing: “We’re looking for a higher level of workforce coming into the mill than what was required 20 years ago.”

-

Sun Paper

Arkadelphia, ARA pipeline to a technology-based workforce is one of the reasons Chinese government-owned Sun Paper made the decision in 2016 to build a $1.3 billion paper mill near Arkadelphia in southwest Arkansas.

More than 28,000 people are directly employed by the timber industry in Arkansas — a workforce that Bob Grygotis, general manager of Domtar in Ashdown, says is changing: “We’re looking for a higher level of workforce coming into the mill than what was required 20 years ago,” said Grygotis. “Our technology is advanced, and we have computer controls on our equipment. So, it’s not so much about the muscle anymore, it’s about what is between the ears.”

A pipeline to a technology-based workforce is one of the reasons Chinese government-owned Sun Paper made the decision in 2016 to build a $1.3 billion paper mill near Arkadelphia in southwest Arkansas. The mill will utilize forest bio-products, which include logging leftovers, dead wood, and non-commercial trees that are thinned from crowded and fire-prone forestland. At capacity, the plant will have 250 employees making an average annual salary of $52,000.

Georgia-Pacific operates one of the world’s largest forest-products complexes in Crossett, which is located in deep south Arkansas. In the facility, Georgia-Pacific makes national name-brand paper products such as Angel Soft and Quilted Northern bathroom tissues, and Sparkle paper towels. The Crossett facility employs 1,100 people and generates 715,000 tons of paper products annually.

We’re looking for a higher level of workforce coming into the mill than what was required 20 years ago. Our technology is advanced, and we have computer controls on our equipment. So, it’s not so much about the muscle anymore, it’s about what is between the ears. Bob Grygotis, general manager, Domtar Georgia-Pacific has been an innovator in the use of public-private partnerships in the development of a technology-based workforce. In 2016, the company partnered with the University of Arkansas at Monticello College of Technology-Crossett to educate the highly skilled workforce required for today’s industry. The Federation for Advanced Manufacturing Education (FAME) program combines classroom teaching and on-the-job training. It’s beneficial for the company, obviously, but more so for the students who receive a free education — Georgia-Pacific pays for tuition, fees, books, and supplies — and a job at the mill starting at $12 per hour with the promise of full-time employment upon successful completion of the program.

“We noticed a significant skill gap in the market and knew we needed to improve that,” said Chris Clark, senior human resources manager at Georgia-Pacific. “So, we took the initiative and developed what I believe will become a model partnership between industry and workforce education.”

Healthy forests, a modern transportation infrastructure for ease of delivery, and an available highly trained workforce are Gov. Hutchinson’s main selling points for attracting the timber industry to the state. “We’ve got the supply. We’ve got an abundance of natural timber that can be utilized for a variety of purposes. We have the workforce that is experienced in the industry, and we have access to the marketplace. All of those are reasons that Arkansas is the perfect fit for expansion in the forest products industry,” said Gov. Hutchinson.

Economic Impact (2016) | |||

| Direct Employment | 28,057 | ||

| Direct, Indirect, and Induced Employment | 69,812 | ||

| Annual Value Added Impact | $6.3 billion | ||

| Annual Payroll | $1.457 billion | ||

| Average Compensation | $51,939 | ||

| Value of Standing Timber | $12.6 billion | ||

Arkansas’ Timber Basket By the Numbers

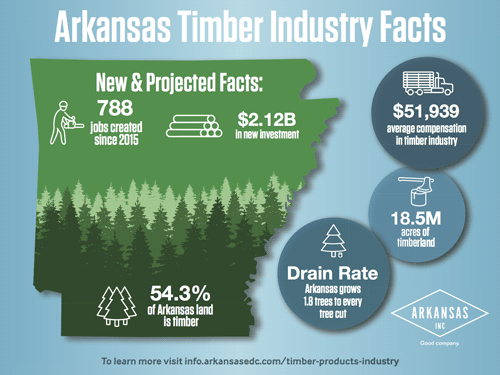

Expansion and announced projects illustrate the resurgence in Arkansas’ timber industry.

-

Georgia-Pacific (expansion)

Gurdon, AR$55 million investment

-

Glatfelter Advanced Materials (expansion)

Fort Smith, AR$80 million investment

-

enviraPAC (expansion)

Monticello, AR$53 million investment

-

Kimberly-Clark (expansion)

Maumelle, AR$40 million investment

-

Highland Pellets (announced)

MPine Bluff, AR$229 million investment

-

Caddo River Forest Products (announced)

Glenwood, AR$50 million investment

-

Sun Paper (announced)

Arkadelphia, AR$1.3 billion investment

-

Conifex (announced)

El Dorado, AR$80 million investment