Making a Proximal Location Decision

Aug/Sep 09

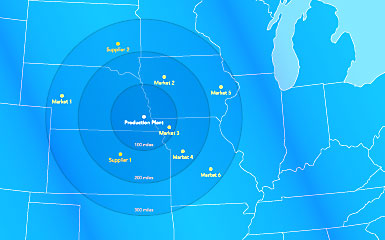

We recognize that choosing the location for a new facility has become a complex, yet strategic, move that can equally spell success or failure for a company's business, especially when it comes to the placement of production plants and distribution centers. But none of the locations you may have under evaluation will be ideal if proximity to markets and suppliers isn't considered.

Three major factors weigh heavily in the proximity decision: Dispersion of markets and suppliers, transportation cost, and green initiatives.

Dispersion of Markets and Suppliers

Markets are recognized as where the finished goods are sold. If your company makes product that is sold universally, i.e., anywhere in the country or world, then locating a plant close to your customers is less important in the site selection decision. However, if your company makes product that is sold only regionally or even locally, then locating a plant close to your customers becomes more important in the location decision.

On the supply side, if your company receives raw materials and components from vendors around the country, and even around the world, then locating a plant close to those suppliers is less important in the selection of a new site. However, if the majority of your suppliers are already - or could be - located within a defined radius, e.g., an area of 250-400 miles, then locating your plant closer to your suppliers will be more important.

Once you perform an analysis of this dispersion, you're unlikely to find a situation where you can satisfy both proximity issues simultaneously in your location decision. Every cost reduction you find by moving closer to markets will probably be offset to some extent by the cost of being further away from suppliers - and vice versa.

Transportation Cost

As a function of logistics, transportation can be a significant factor in the cost of goods sold, and thus is an important consideration in the site selection decision. Depending upon the industry and products, it can be as little as 5-10 percent of the cost or as much as 30-40 percent. Transportation cost is a variable function of time, distance, size, mode, and fuel cost.

The longer the distance, the less restrictive the pick-up and delivery, the larger the shipment size, the more common the mode of transportation, and the lower the cost of fuel, the less it will cost per mile to move freight from point A to point B. Conversely, the shorter the distance, the more restrictive the pick-up and delivery, the smaller the shipment size, the more unique the mode of transportation, and the higher the cost of fuel, the more it will cost per mile to move freight from point A to point B.

Time - Here are some questions to consider in the time equation: Are your shipments going directly to manufacture, to retail, or to be placed in inventory elsewhere in the supply chain? Are they in support of any just-in-time operations, which will dictate the pick-up and delivery parameters? The answers to these questions will also drive the mode of transportation that will be needed.

Distance - The length of haul between the points of origin and destination are a big part of the transportation cost. A shipment generally moving 1,500 miles will travel at less cost per mile than a shipment moving 500 miles. This also impacts the time element. A good rule of thumb is to add one day for every 250 miles from point A to point B.

Size - For purposes of this example, we'll stick with domestic surface transportation. If a shipment weighs less than 10,000 pounds and only occupies part of a trailer, it is likely to be a less-than-truckload (LTL) shipment that will be moved by a regular-route, network-based LTL carrier. Network means there may be multiple transfer points depending on how far the freight moves. If the shipment weighs more than 10,000 pounds (and less than 40,000-45,000 pounds) or occupies the majority or all of a trailer, it is likely to be a full truckload (TL) shipment that will be moved by an irregular route TL carrier.

Mode - LTL, TL, dry van, refrigerated van, and flatbed shipments will move over-the-road. Some over-the-road shipments can also move as intermodal via the rails. Bulk shipments can also be moved on the rails via boxcar. The options are many regarding the mode of transportation that can be selected. Also a function of a time, intermodal is generally slower than truck.

Fuel Cost - Over the past year, the cost of fuel has played an increasingly important role in the cost of transportation. In July 2008, the retail price for diesel peaked at about $4.75 per gallon. And just nine months later, it reached a pre-2007 low of $2.00 per gallon. To recover the additional cost of fuel, carriers will impose a fuel surcharge, often as a percentage of the revenue on the freight bill. Fuel surcharges are negotiated between the carrier and the shipper, but most seem to use $1.10 a gallon as the base point. The fuel surcharge for diesel at $4.75 would be much higher than at $2.00. In some cases, the cost of moving the freight could nearly double. Trucking surcharges are generally higher than intermodal surcharges.

Project Announcements

Cascades Expands Eau Claire, Wisconsin, Operations

12/25/2025

P.C. Campana Plans Vicksburg, Mississippi, Production Operations

12/25/2025

Midwest Equipment Manufacturing Expands Maysville, Kentucky, Operations

12/25/2025

Stord Expands Hebron, Kentucky, Warehouse Operations

12/25/2025

Edelweiss Dairy Expands Freedom, New York, Operations

12/24/2025

Hut 8 Plans West Feliciana, Louisiana, Data Center Operations

12/24/2025

Most Read

-

The Workforce Bottleneck in America’s Manufacturing Revival

Q4 2025

-

Rethinking Local Governments Through Consolidation and Choice

Q3 2025

-

Lead with Facts, Land the Deal

Q3 2025

-

Investors Seek Shelter in Food-Focused Real Estate

Q3 2025

-

Tariff Shockwaves Hit the Industrial Sector

Q4 2025

-

America’s Aerospace Reboot

Q3 2025

-

The Permit Puzzle and the Path to Groundbreaking

Q3 2025