A sustainable master plan is a comprehensive long-term roadmap for a site’s (and its buildings) development, with particular interest paid to maximizing operational efficiency. You may be surprised I didn’t say that sustainable master plans should focus on being “green.” However, at the most fundamental level, green design and minimizing environmental impact are just the result of efficiency. To me, efficiency — saving time and money — equals sustainability. The business goal should be reducing the total ownership cost (TOC) of any operation. If that is achieved, the result is inherently “green.”

An Eye Toward the Future

The great thing about master planning is the attention being directed by an operation’s senior management toward the future; this provides the perfect opportunity to integrate implementation of sustainable features that support long-term performance and company objectives. Sustainable master plans set the stage for a continued commitment to efficiency — minimizing inputs and reducing waste — which has never been more important in the industrial sector.

Understanding the concept of TOC is a turning point for many industrial executives, When you start to drill down, you realize that items like first capital costs pale in comparison to long-term costs such as maintenance, material inputs, energy, and labor.

In the 1990s and early 2000s, manufacturers were sending labor overseas at alarming rates; the U.S. simply couldn’t compete with China’s low wages. But Chinese labor rates have risen sharply in the last several years, growing by more than 10 percent annually. This, combined with concerns about the stability of global supply chains, dramatic reductions in energy costs, and the inability to protect intellectual property, is prompting the return of business to the United States and Mexico.

“Re-shoring,” as it’s called, has breathed new life into economic development initiatives throughout the southern U.S. and Mexico, in particular, and manufacturers are now breaking job-creation and financial growth records. In fact, the South and Mexico stand to become the leading industrial clusters in coming years if growth trends continue. Meeting this expectation requires financial competitiveness, while many U.S. consumers also expect social responsibility. Both of these objectives can be achieved with efficient planning. Therefore, a sustainable master plan plays an ever-increasing role in a company’s preparing for success.

Defining Objectives

When industrial executives work with planners, architects, and engineers to develop sustainable master plans, there are many things to consider. First and foremost, it is key to clearly define business objectives: what is the long-term vision for the company, and what are its mid-term goals? What are the growth objectives? What is the time horizon? How rapidly is the business evolving? What are the financial considerations and budget constraints? The answers to these questions significantly impact the master planning approach and recommendations. The key to good planning is to understand a company’s business plan, process flow, and employee population. But the best solution is not always obvious.

On a recent project, our team worked with a company that planned to build a new manufacturing facility combined with its U.S. headquarters. It would be the company’s home base for a minimum of 20 years. We looked at many different sites throughout the southeastern U.S. In the course of the site selection process, the company was offered an existing site and building that was state-owned at no cost. Since it was “free,” it sounded like a great deal.

At our client’s request, our team prepared an analysis of the offer. One item we evaluated was the efficiency of the site and building as it related to our client’s business. While it would work for the client’s operation, the resulting process flow was overly long and narrow. In this existing building, the process flow would not be nearly as efficient as it could be. We quickly estimated that the cost of lost productivity would offset the “free” facility in less than five years. Given our client’s business objectives and time horizon, the “free” building was very, very expensive. The total ownership cost (TOC) would have been quite high.

Understanding TOC

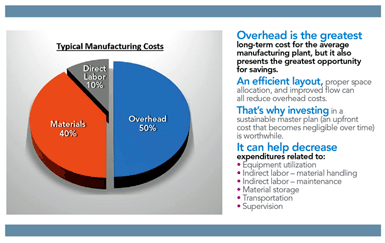

Understanding the concept of TOC is a turning point for many industrial executives, but getting a solid grasp on the big picture of a facility’s expenses is essential. When you start to drill down, you realize that items like first capital costs pale in comparison to long-term costs such as maintenance, material inputs, energy, and labor. Designing and constructing smartly — with the goal of reducing those bigger expenses — is good business and sustainable.

As technology rapidly evolves, it is important to revisit past decisions. When LED lighting entered the consumer market the packaging announced that after a year’s time, an LED bulb could save us close to $100 in electric bills, paying for itself 10 times over. But as an architect, I don’t believe something until I see data backing it up.

Our team analyzed the use of LED fixtures in many industrial plants and found they simply did not have a viable payback for most of our clients. But this has changed in the last two years. Recently, we performed a new analysis for a major manufacturing facility and found that with improvements in the technology and reduced price per fixture, we could achieve proven long-term cost savings and greatly reduced energy consumption. We were able to reduce TOC.

Other costs like insurance should also be considered in order to paint an accurate operational cost picture and help a company make the best decisions. On another recent project, based on our experience, we recommended several firewalls in a facility. These walls were not required by building code, and our client did not want to bear the first cost. But a review of the long-term impact to their insurance rates changed its mind.

Impact on Employee Productivity, Morale

Another factor that many decision-makers don’t fully consider is the impact that site selection and facility design can have on employee productivity. It is often in a company’s best interest to spend incrementally more in first costs to improve the working environment. This will improve employee loyalty, recruitment, and retention.

Another factor that many decision-makers don’t fully consider is the impact that site selection and facility design can have on employee productivity. It is often in a company’s best interest to spend incrementally more in first costs to improve the working environment. A few years ago, I had the pleasure of working with a major transportation company in the site development and design of its operation’s headquarters. The company CEO had a true TOC mindset. He was willing to spend incrementally more at the beginning of the project to save money in the future.

One area where we spent extra design time and extra construction cost was the employee cafeteria. A year after the project was built, I visited the facility and had a conversation with an employee. She told me, “This place is nicer than my house; I get here a half-hour early every morning just to enjoy it.” I was stunned. Over the years, this company has seen low turnover, low operating costs, low maintenance costs, and great business success.

A Valuable Investment

A smart, well-designed, efficient site and building that supports smooth process flow and high output helps companies avoid overstaffing and unnecessary related costs. Paying attention to details and being willing to spend incrementally more at the beginning of a project will provide benefits for the life of the facility. The long-term outcome is increased productivity and profit, and reduced expenditures: a win/win from both a financial perspective and a sustainability perspective.

Sustainable design is more attainable and affordable than it’s ever been, especially when you think in terms of years instead of days and weeks. It’s also worth noting that sustainable design is very well favored among the public, which is an extra incentive for companies interested in reinforcing their reputation as socially responsible and environmentally concerned.

Working with a planning team that can put pen to paper and assess the specific ways that long-term savings trump short-term costs is essential. Solid TOC calculations inspire confidence in what will likely be a very valuable investment. The result of analyzing total ownership costs and purposefully implementing a sustainable master plan is doing more with less, which, in my perception, is truly sustainable.