Projects involving the manufacturing, processing, handling, or storage of explosives, ammunition, or other energetic materials are among the most demanding for any engineering or construction firm.

Unique challenges arise at every turn, requiring a meticulous approach, a deep understanding of safety protocols, and the ability to navigate complex regulatory frameworks. These projects demand extraordinary attention to detail, as success is defined by an uncompromising focus on the safety of all personnel working within and near these facilities.

A detailed understanding of the Department of Defense Contractor's Safety Manual for Ammunition and Explosives (DOD 4145.26) is fundamental to the success of these projects. This manual serves as a comprehensive safety framework that requires more than simple compliance; it demands a rigorous process for assessing how explosives impact buildings, equipment, and personnel from initial planning through construction and final facility turnover.

Before engineering design can begin, a thorough understanding of the specific energetics involved is required. Evaluating explosive properties includes calculating net explosive weight (NEW) and modeling maximum credible event (MCE) scenarios. Storage, handling protocols, and historical incident data must be examined to establish a strong foundation for safety and design decisions.

One critical tool in this phase is a quantitative risk assessment (QRA), also referred to as a process hazard analysis (PHA) on some sites. This process involves detailed hazard assessments and blast modeling, providing critical insights for design decisions.

Projects involving explosives demand extraordinary attention to detail—success is defined by an uncompromising focus on safety.

Proper categorization and classification of materials are foundational to safety evaluations in chemical and explosive handling. Chemists may be needed to classify materials and assess volatility if properties are not well established. Material tests may be necessary to determine the precise properties of ordnance.

Developed processes can rely more heavily on published safety data sheets (SDS) or a history of field tests. Evaluating materials, total quantities, usage, and potential interactions significantly impacts facility criteria. Some ingredients, when packaged, may be treated as inert but can create explosive dust particulates upon processing. Exposed energetics drive the highest safety concerns, requiring the most stringent facility requirements.

From Siting to Design Approval

Selecting the right site and obtaining necessary approvals are pivotal. Site layout must balance operational needs with safety, achieved through one of three approaches:

Avoidance: Using quantity distance (QD) arcs to separate hazardous areas.

Prescriptive Design: Relying on preapproved designs.

Custom Protective Construction: Creating tailored designs based on detailed analysis.Each approach requires rigorous documentation and coordination with the Department of Defense Procurement Contracting Officer (PCO) to maintain compliance.

Advanced blast-resistant technologies are critical for protecting personnel and assets. These include fire- and blast-resistant materials for structural components, specialized wall materials to minimize debris, and innovative solutions such as liquid body armor and carbon nanotubes. High-performance laminated glass and layered concrete further enhance safety by dispersing blast energy.

150

Several key principles contribute to effective explosives facility design, such as using convex building exteriors to deflect shock waves, employing strategic ventilation systems to reduce pressure buildup, and avoiding reentrant corners to prevent amplification of shock waves.

These measures, combined with advanced materials, create resilient structures capable of withstanding potential blast impacts.

A proactive approach to identifying hazards is essential. This includes evaluating flammable materials, high-risk processes, and proximity to other industrial facilities containing similar explosive materials. Lessons from past incidents help inform design and operational protocols.

Compliance with industry standards from the American Petroleum Institute (API), American Society of Civil Engineers (ASCE), National Fire Protection Association (NFPA), and International Organization for Standardization (ISO) ensures alignment with best practices and regulatory requirements.

Modern computational tools enhance design efficiency. Artificial intelligence and machine learning optimize designs by simulating various scenarios, while additive manufacturing enables rapid prototyping. Computational modeling provides precise blast effect predictions, allowing designers to refine protective measures.

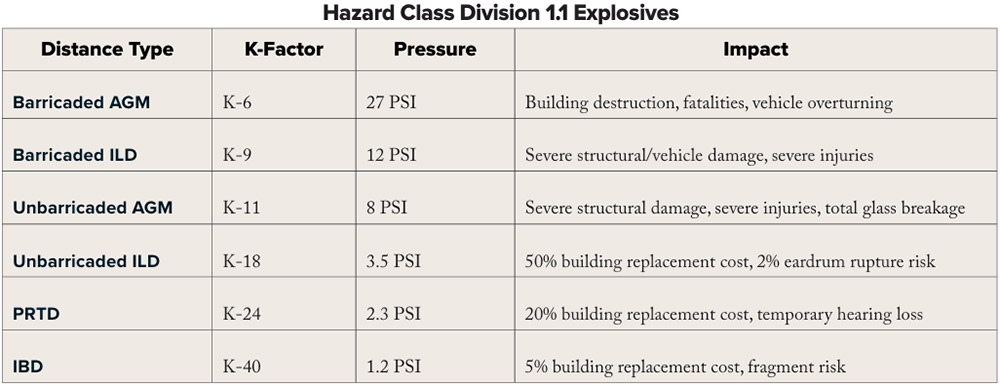

Setback distances for explosive storage and handling are critical for safety and regulatory compliance. The impact of explosives decreases exponentially as distance increases. Key principles include reducing explosive quantities and minimizing exposed populations.

Allowable activities vary by distance type. Land use considerations are significant, often requiring extensive safety buffers. A single building with 450 pounds of explosives may need 150 acres. Efficient land use strategies include grouping similar hazard operations and utilizing agricultural or natural areas as buffer zones.

Despite the complexity of explosives facility design, common pitfalls are vast, and can include things like overlooking fragmentation hazards; misapplying inhabited building distance (IBD) or intraline distance (ILD) standards; ignoring the compatibility of mixed substances; failing to account for backup power needs, such as diesel tanks; failing to document distances to utility needs (power, water, sewer); and locating sensitive areas near off-campus operations.

The impact of explosives decreases exponentially as distance increases, making setback distances a critical factor in site selection.

Navigating the complexities of explosives facility design requires an experienced, multidisciplinary team. From calculating blast effects to maintaining regulatory compliance, a team with the right expertise provides balanced designs that prioritize safety without compromising functionality.

Designing facilities for explosives is a high-stakes endeavor. Every element, from site selection to material choice, plays a crucial role in safeguarding lives and assets. By embracing a methodical approach and leveraging the latest technologies, operators can manage risks, avoid common pitfalls, and deliver projects on time and within budget. In this field, thorough preparation and an unwavering commitment to safety are not just best practices — they are nonnegotiable.