Traditional industrial robots still have a place when things have to be done repeatedly, quickly, and without mistakes, but advanced robotics technology is enabling a new set of robots, called collaborative robots, to assist in areas other than manufacturing. Collaborative robots can handle a multitude of tasks because they can think for themselves. They’re a combination of artificial intelligence, sophisticated vision systems, and mechanical engineering. This means they can teach themselves about their surroundings, work safely alongside humans, and address the challenges of aging workforces and more demand for customization — not to mention escalating labor and production costs.

The interest in collaborative robots makes sense in today’s world. Globally, collaborative robots represent one of the fastest-growing categories of the robotics industry, with shipments expected to grow from $100 million to $1 billion by 2025 - a tenfold increase, according to an ABI Research Study.

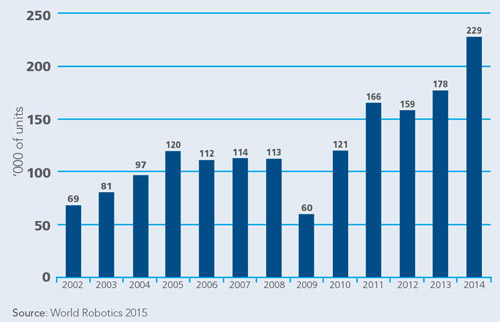

This growth matches the global demand for all categories of robotics, which will continue to grow through this decade to a market value projected to reach $41 billion by 2020. According to the International Federation of Robotics (IFR), in 2014, robot sales increased by 29 percent to 229,261 units, by far the highest level ever recorded for one year. In comparison, an average of 171,000 units per year were sold between 2010 and 2014.

Najah Ayadi, President of Bluewrist Inc., a provider of industrial automation solutions and products based in Richmond Hill, Ontario, Canada, believes new robotic technologies make good business sense. “This new generation of safe robots can deliver a return on investment within one year on average.”

Improving Quality and Safety

But it’s not just dollars and cents. Collaborative robots, along with robotics and autonomous systems in general, can help manufacturers improve quality, accuracy and, most importantly, worker safety. Robots are working alongside humans using artificial intelligence to evaluate their environments and use rational processes to step in when conditions are unsafe or workers need a helping hand. Collaborative robots are enhancing the way humans live and operate, and there are examples of this robotic renaissance happening in North America.

Small Businesses/Big Aspirations

U.S. robot installations — the third-largest robot market — continued to increase, by 11 percent to the peak of 26,200 units, according to the IFR. Driving this growth are improvements in automated production to maintain domestic manufacturing, the IFR notes, and in some cases, to bring back manufacturing that had previously been sent overseas.

Like other disruptive technologies in the United States and globally, the formative advancements can be seen in startups that operate on small budgets and big aspirations. In the U.S., that includes companies such as Dispatch, a Silicon Valley company that is testing an autonomous delivery vehicle - a smart-box on wheels - on two American college campuses.

Marc Benioff, CEO of Salesforce, a titan in Silicon Valley for the past two decades, wrote recently that robots, particularly their use of artificial intelligence (AI), will soon become as ubiquitous and underlying in our lives as electricity: “As in past periods of economic transformation, AI will unleash new levels of productivity, augment our personal and professional lives, and pose existential questions about the age-old relationship between man and machine.”

Robotics Systems Manufacturing, Education and Research Programs in Ontario, Canada

-

Bluewrist Inc., Richmond Hill, Ontario, Canada

Najah Ayadi, President of Bluewrist Inc., a provider of industrial automation solutions and products based in Richmond Hill, Ontario, Canada, believes new robotic technologies make good business sense. “This new generation of safe robots can deliver a return on investment within one year on average.”

-

Clearpath Robotics, Kitchener, Ontario

Autonomous vehicles and devices, such as those developed by Clearpath Robotics of Kitchener, Ontario, Canada, can travel on land or under water, proving useful in unsafe conditions such as an oil spill or fast-moving water

-

KUKA Robotics Canada Ltd., Mississauga, Ontario

“Today’s systems are far more intuitive and easier to program, as well as more accessible to business owners. Today you don’t need an engineering degree to program a robot or system. So anyone can benefit.” - Chris Claringbold, CEO of KUKA Robotics Canada Ltd., a robotics systems manufacturer based in Mississauga, Ontario

-

The Robotics and Control Group at Ontario’s Western University

In Ontario, 24 of the province’s colleges offer automation and robotics-related programs, with applications in robotics, automation, controls, electronics, and mechatronics. The Robotics and Control Group at Ontario’s Western University is equipped with state-of-the-art tools including virtual reality and haptic devices, along with a wide variety of robots such as the Magellan Pro Mobile Robot.

-

David R. Cheriton School of Computer Science at the University of Waterloo

The David R. Cheriton School of Computer Science at the University of Waterloo conducts top-tier research, specifically in the fields of artificial intelligence and human-computer interaction. This focus provides the talent required to undertake robotics-related research, such as space robotics, drone technologies, autonomous ground vehicles, and underground/underwater applications.

Skilled Labor

But what is required to be a leader in industrial automation and robotics - and critical for success is skilled labor. In Ontario, 24 of the province’s colleges offer automation and robotics-related programs, with applications in robotics, automation, controls, electronics, and mechatronics. The Robotics and Control Group at Ontario’s Western University is equipped with state-of-the-art tools including virtual reality and haptic devices, along with a wide variety of robots such as the Magellan Pro Mobile Robot. Additionally, The David R. Cheriton School of Computer Science at the University of Waterloo conducts top-tier research, specifically in the fields of artificial intelligence and human-computer interaction. This focus provides the talent required to undertake robotics-related research, such as space robotics, drone technologies, autonomous ground vehicles, and underground/underwater applications.

In the U.S., robotics education and research programs are offered at the Institute for Robotics and Intelligent Machines at Georgia Tech, Carnegie Mellon’s Robotics Institute in Pennsylvania, The Robotics & Mechanisms Laboratory at Virginia Tech, and MIT’s Computer Science & Artificial Intelligence Laboratory, among many other colleges and universities too numerous to list here.

Additionally, community colleges are helping to satisfy the robotics industry’s need for skilled labor. For example, Applied Manufacturing Technologies (AMT), a Robotics Industries Association (RIA) Certified Robot Integrator based in Orion, Michigan, recruits workers from community colleges as well as universities. According to Diane Haig, the company’s Chief Knowledge Officer, “Automation engineers (typically four-year degrees) have exposure to and an understanding of how the different engineering disciplines go together to make automation a possibility. They’re familiar with the electronics, the control system, the robots, the mechanical design, and some of the software tools that are used in automation. Coming from a community college, they may be well-versed in one of those disciplines,” she says. “We’ve had people start from the two-year program and develop very quickly and work their way into automation engineer positions.”

As the use of robotics continues to drive business growth in the United States and Canada, particularly in Ontario, satisfying the industry’s need for skilled workers will continue to be a top priority.