With low business costs, top transportation infrastructure, and close proximity to natural resources, the ceramics industry in Tennessee is booming. More than $152 million in ceramic products are exported annually. The Volunteer State ranks first in the U.S. for growth in ceramics employment concentration and establishments.

Due to high product demand, employment in the ceramics industry in Tennessee has grown about 25 percent since 2018. Over this time period, the Tennessee Department of Economic and Community Development (TNECD) has helped secure $350 million in capital investment for new ceramic-related location and expansion projects, along with more than 575 new job commitments.

“This is an exciting time in the ceramics industry in Tennessee,” said Edward Burch, director of Business Development for TNECD. “The demand for quality ceramic tile coincides with housing growth and remodeling projects across the country. New investment has resulted in product advancements — more durability, higher quality, style. And greater outdoor use has increased the market share.”

A prominent trend in the industry is large unit "gauged porcelain” (3.5' x 10' size) tiles for countertops, walls, exterior building cladding, and even furniture. Builders are also using more exterior porcelain pavers in 3/4" thick units in their residential and commercial projects for exterior decks, walkways, and driveways.

“Both large and small porcelain tiles with a polish are now mainstream products,” added Burch. “Automation and state-of-the-art facilities are becoming more commonplace in the ceramics manufacturing process — the technology being used to produce these products has made more advancements in the last five years than in the previous 30 years combined.”

Location, Location, Location

Tennessee’s central location and well-integrated transportation infrastructure allow ceramics manufacturers to reach a majority of the U.S. population in about a day’s drive. The state has nearly 12,000 miles of interstate highway, six commercial airports (including Memphis International Airport, one of the busiest cargo airports in the world), and 29 rail systems. Memphis is also the fifth-largest inland port in the U.S. These transportation assets make Tennessee ideal for warehousing/logistics industries and just-in-time manufacturing, inventory management, and last-mile delivery.

Another big advantage for ceramics manufacturers is that Tennessee produces all the critical materials they need. Major manufacturers in the ceramic tile industry such as Florim USA, Dal-Tile Corporation, Landmark Ceramics, Rainbow, and Smalticeram USA greatly benefit from the abundance of Tennessee’s natural resources and raw materials, especially feldspar and ball clay.

In fact, Tennessee is the number-one state in the country for ball clay mining; 90 percent of all tile manufactured in the U.S. includes Tennessee ball clay. In particular, Weakley County is home to some of the largest ball clay deposits in the country, where four large-scale mining operations provide ball clay. Such close proximity to abundant natural resources greatly reduces transportation costs for ceramics manufacturers. Baxter, located in Putnam County, is another prominent cluster for the production of porcelain tile due to the abundant natural clay and feldspar supplies in the area.

TNECD collaborates with regional and local governments, industry, and educational institutions to develop a customized workforce and curriculum for the ceramics industry. TNECD also maintains a number of international FDI offices so it can meet potential clients in their home countries and tour their operations. “Ultimately,” said Burch, “we believe in collaboration with leaders in the ceramics industry and understanding their needs for growth and support.”

Recent ceramics announcements include:

- Italian porcelain floor and wall tile manufacturer Florim USA recently invested $35 million to expand its factory in Clarksville, creating more than 30 jobs. Highly automated operations at the new plant include body preparation, glaze preparation, pressing, glazing, kiln, rectification, polishing, selection, and packaging. “For over a decade, Florim USA has invested in state-of-the-art production processes and other enabling technologies,” said Florim USA president Antonio Albanese. "We’ve seen the great success and tremendous opportunity that has been created from our continued partnership with the state of Tennessee.”

- Portobello America recently started production at its new plant in Baxter — its first factory outside its home country of Brazil. “The ceramic market in the U.S. is one of the largest and most attractive in the world — and is essential to our international expansion strategy,” said Cesar Gomes, chairman for Portobello Grupo. The new $200 million facility, equipped will the latest technologies and equipment, covers an area of nearly one million square feet. There is also plenty of room for future expansion on the 95-acre site.

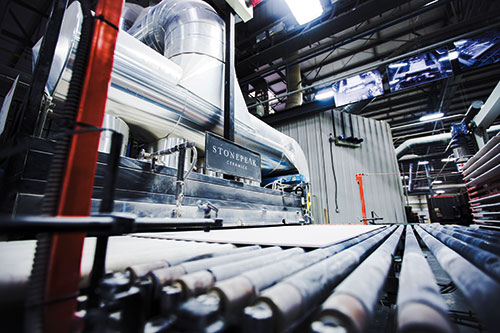

- Stonepeak Ceramics, a U.S. manufacturer of porcelain surfaces, will invest $10 million in capital improvements to upgrade its existing manufacturing facility in Crossville. Capacity will be enhanced by installing digital production technologies and quality systems. The company will also use a cloud-based warehouse management program to improve efficiencies, reduce inventory costs, and speed up delivery as consumer demand for its products increases.

Another key factor that draws ceramics companies to Tennessee is the presence of a strong international supply chain, “including most of the global industrial players such as Sacmi, System Group, BMR, LB, Silvestrini, Martinelli Stampi, Rainbow, Hydrodesign, Torrecid, and GMM e Colorobbia,” indicated TNECD’s director of business development Virginia Crowley.

We believe in collaboration with leaders in the ceramics industry and understanding their needs for growth and support. Edward Burch, director of Business Development for TNECD Crowley oversees one of five TNECD’s international recruitment offices. In total, these offices cover 12 countries across Europe and Asia. Based in Italy, Crowley can attest to the high demand for raw materials needed in the tile industry and works with many Italian tile manufacturers to promote how Tennessee can support and expand their global footprints.

For an international company that is planning to approach a new market, “knowing there is a history of companies that operate in its industry and have successfully established their U.S. presence — creating a district that provides all the necessary elements to facilitate doing business — is a huge advantage,” said Crowley. “Tennessee offers an industrial supply chain that no other state has. The state is a nurturing environment, where businesses can flourish, and an industrial culture exists.”

Ceramics manufacturers also know that TNECD has a longstanding reputation as a supportive “one-stop-shop” that connects companies with appropriate stakeholders and innovative thinkers to find solutions and solve challenges.

“For ceramics companies new to Tennessee, TNECD offer assistance in finding quality sites that can support their operation, along with assistance in getting proper permits in place and providing direct connection to assisting state agencies,” added Burch. “Our pro-business leadership — coupled with easy access to resources and raw materials and a highly skilled workforce — positions Tennessee well for further growth in the ceramics industry.”