Sometimes You Have to Move; Sometimes You Don’t.

Structural precast building materials can give you options.

Q2 2019

Running a growing business is a lot like overseeing a growing household. As your business grows, your physical requirements change. Sometimes you need to move and there’s no getting around it; other times you can address changing needs with a little remodeling. One of the many benefits of a business home built with structural precast is its modular nature. Your biggest constraint may be the boundaries of your property.

The individual panels of a structural precast envelope are self-contained, wholly independent, modern engineering wonders. Each panel features an interior and exterior finish, insulation up to R-28.2, and full load-bearing capabilities. Once built, the engineering of the product enables a great deal of flexibility. The adaptability and versatility of precast panels mean expansion and modification are no obstacles. This means, whether your structure is experiencing growing pains or you’re in need of a few aesthetic changes, precast can grow with your business.

The modular construction of a precast building gives you the option of modifying your layout. Changing your building’s functionality, enlarging or reducing your footprint, or repairing cosmetically damaged panels are all tasks that become simpler when working with precast. It’s even possible to take existing panels and “up-cycle” them into the construction of a new edition. Just like home improvement projects, the scale of your plans will impact what type of subcontractors need to be involved. Structural precast panels are a highly engineered building material.

They are, after all, load-bearing. So, while it’s entirely possible to add windows, service doors, and even dock doors at any point in the life of the building, you will need to work with an engineer or the manufacturer of the panel.

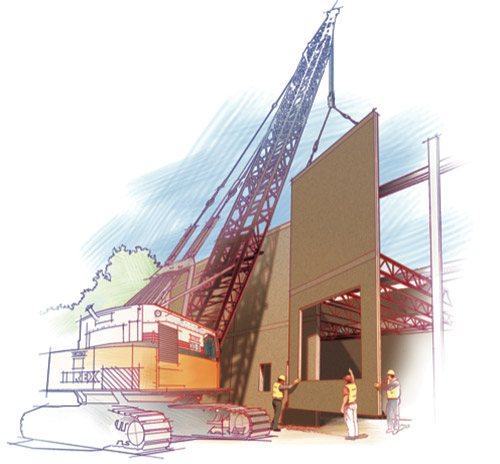

Sometimes you simply outgrow your home and nothing short of adding additional square footage is acceptable. In those cases, a precast “bump-out” might be the most attractive solution. Moving is expensive and disruptive. It’s hard to execute a move and not experience some form of time loss or costly shutdowns. When expanding a precast building, the work is usually isolated and normal activities can continue without compromise. Even if you already have a non-precast building, structural precast may be your best option. With a little creativity, a precast expansion is a strong possibility for almost any kind of structure. If you have the space to expand, it’s likely you can still achieve your goals.

For over 45 years, Fabcon Precast has been a leading force in structural precast concrete construction. Fabcon Precast is an ideal partner for the most aggressive timetables and the most modest of budgets. If it feels like your current business home is getting too cozy, let us know…you’ve got options. And if you’re interested, we can always talk about building that “forever home” from scratch. It’s never too early to start dreaming.

Project Announcements

Wyandot Snacks Expands Marion, Ohio, Production Operations

08/29/2025

Trane Technologies Expands Fort Smith, Arkansas, Operations

08/29/2025

BioMADE Plans Boone, Iowa, Bioindustrial Manufacturing Operations

08/29/2025

Choice Fabricators Expands Rainbow City, Alabama, Production Operations

08/29/2025

Ranovus Expands Ottawa, Ontario, Semiconductor Operations

08/29/2025

Belgium-Based Stow Group Plans Gordon County, Georgia, Manufacturing Operations

08/28/2025

Most Read

-

Tariffs, Talent, and U.S. Expansion

Q3 2025

-

What We’re Getting Wrong About Gen Z’s Future in the Skilled Trades

Q3 2025

-

Data Center Demand Stabilizes Amid Changing Market Forces

Q3 2025

-

A New Course for U.S. Shipbuilding

Q3 2025

-

Optimizing Your Rail-Served Transportation Network: Strategy Before Steel

Q2 2025

-

In Focus: AI Is Changing Incentives Math

Q2 2025

-

Rewriting the Rules of Warehouse ROI

Q3 2025