Inbound-Outbound Logistics Cost Determines Location Decisions

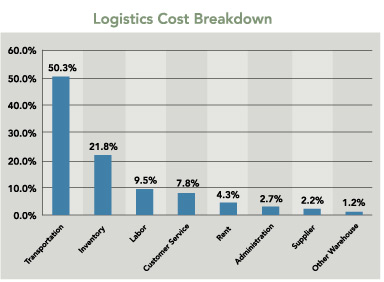

The majority of respondents to Area Development's 24th Annual Corporate Survey said inbound-outbound shipping costs were important to selecting a site. Consider these factors before your next move.

June/July 10

Future implications of inbound-outbound shipping costs on distribution networks should concern corporate managers. The volatility of fuel costs, accessibility of other modes of transportation, and major legislation currently being debated have given corporate managers a new list of worries. But building a robust distribution network can alleviate future problems.

Project Announcements

Hut 8 Plans West Feliciana, Louisiana, Data Center Operations

12/24/2025

Coley Home Expands Claremont, North Carolina, Manufacturing Operations

12/24/2025

South Korea-Based ALUKO Group Plans Halls, Tennessee, Aluminum Manufacturing Operations

12/24/2025

Hoffman & Hoffman Expands Greensboro, North Carolina, Headquarters Operations

12/24/2025

Fenner Precision Polymers Plans Gaffney, South Carolina, Manufacturing Operations

12/24/2025

Mission Critical Interior Solutions Plans Springfield, South Carolina, Manufacturing Operations

12/24/2025

Most Read

-

The Workforce Bottleneck in America’s Manufacturing Revival

Q4 2025

-

Rethinking Local Governments Through Consolidation and Choice

Q3 2025

-

Lead with Facts, Land the Deal

Q3 2025

-

Investors Seek Shelter in Food-Focused Real Estate

Q3 2025

-

Tariff Shockwaves Hit the Industrial Sector

Q4 2025

-

America’s Aerospace Reboot

Q3 2025

-

The Permit Puzzle and the Path to Groundbreaking

Q3 2025