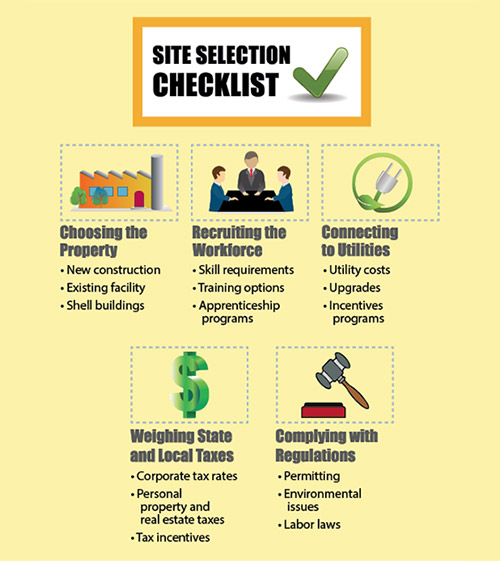

Logistic requirements tend to define the initial target area for manufacturing projects. A target area might range in size from anywhere in the U.S. to a focused zone along a particular interstate. Once the target area is defined, however, five geographically variable inputs dominate the site selection process, with final decisions often involving tradeoffs among these factors:

- Availability of property

- Recruitment and training of workers

- Cost and reliability of utility service

- State and local taxes

- Regulatory climate

Availability of Property

Industrial vacancy rates are below 5 percent nationwide — and many older “industrial” properties turn out to be glorified warehouse space. That means finding a suitable vacant building may prove to be difficult, especially if the project has specialized facility requirements such as freezer space, special access, or an advanced water-discharge system. Most projects thus require significant improvements to an existing property, or if time and budget allow, new construction. Advanced manufacturers willing to pay top dollar for Class A industrial space will find many more opportunities (albeit still restricted), but most projects are on a tighter budget.

Fortunately, in many communities, there are industrial shell buildings that can be fitted out to specifications in under 18 months. Finding these opportunities or a pad-ready industrial site is not nearly as challenging as finding a suitable existing property, especially if you have partnered with a local economic development organization (EDO).

Recruitment and Training of Workers

Advanced manufacturers are up against three distinct challenges when recruiting and training workers:

- Skill requirements are changing as machine operations become integrated with engineering and computer-assisted manufacturing (CAM) software.

- Cultural bias discourages many qualified young people from seeking a career in manufacturing.

- An aging workforce is making specific positions particularly difficult to recruit (e.g., maintenance, quality assurance).

Foreign-owned advanced manufacturers also are leaders in introducing apprenticeship programs. Outreach to public school systems to encourage young people to consider careers in manufacturing sometimes starts as early as middle school. By the time these students graduate from high school, they (and their parents and guidance counsellors) are familiar with the apprenticeship option. Flexibility is a key feature of apprenticeship programs; recent high school graduates are encouraged to work full time but also enroll in a program leading to an associate’s degree. Upon completion of the degree program, the student is often required to accept a full-time position with the sponsoring company for a limited period of time. This approach, familiar to many foreign companies, is generally offered in the U.S. only by very large manufacturers.

EDOs in every community try to work constructively with manufacturers on workforce training and recruitment challenges. However, the effectiveness of local partners in executing on these strategies varies widely. This variation should be carefully evaluated during the site selection process.

Utility service territories are fragmented and estimating expected cost is complex. Most manufacturing projects have a least one mission-critical utility concern — usually gas or electric reliability and cost, but sometimes including water and sewage. One unique U.S. challenge is the complexity of franchise service territory boundaries, which frequently divide communities. As a result, it is common for price and service to significantly differ between properties located in the same area; a community with a single labor market will often have multiple gas or electric providers.

Many gas or electric utilities are fully engaged in local economic development business recruitment efforts. For example, utilities are often willing to help estimate your project’s future utility costs at a proposed site, based upon past usage. Manufacturers often require service upgrades at the desired property. Although many utilities are willing to help, there is wide variation in how much leeway utilities have to rapidly respond to these requests.

Utilities frequently offer incentive programs. For example, many offer financial support to manufacturers willing to implement demand-side management (DSM) programs such as backup generators for use in interruptible service contracts. And some electric utilities offer reduced economic development rates to entice manufacturers to locate in their service territory. Similarly, a water-intensive manufacturer might be offered significantly reduced water and sewage rates in exchange for installation of an advanced filtration water discharge system. In short, it is almost always worth discussing your new project with the local utility companies, and the local EDO is the quickest way to establish appropriate contacts.

State and Local Taxes

State tax policy with respect to manufacturers varies widely and can significantly impact project costs. However, the taxes that matter most are not the ones companies often focus on. For example, state corporate income tax burdens for manufacturers range from insignificant to major depending on how that state’s apportionment formulas apply to a particular company. Corporate tax rates, therefore, tell you very little, and your tax department should advise as to states where a new plant might trigger unexpected tax consequences. Most states exempt from sales tax the purchase of equipment used in the manufacturing process so frequently this will not be an issue — or is an issue that can be negotiated away.

Two taxes to pay close attention to are business personal property tax (BPPT) and real estate taxes. BPPT is a tax on a company’s machinery and, hence, is particularly important to capital-intensive advanced manufacturers. Moreover, since it is based on the value of equipment after depreciation, it hits new facilities hard, when equipment is new and not yet depreciated. In states with a BPPT, abating or reducing BPPT is often a part of the incentive package offered to advanced manufacturers.

Many gas or electric utilities are fully engaged in local economic development business recruitment efforts and are often willing to help. Local real estate tax is often the most significant tax paid by manufacturers. In the United States, the same property is taxed by multiple jurisdictions (municipal, county, and school district). Most states allow localities to abate the incremental increase in property taxes attributable to the real property improvements made by advanced manufacturers, but this requires local negotiation. While reducing real estate tax is a common business incentive, the rules for abating often vary among the multiple jurisdictions taxing the property. This, too, is an area in which a strong relationship with the local EDO can be extremely helpful.

State business incentives vary widely; programs based on capital investment tend to support advanced manufacturing, while those based on large numbers of highly paid (i.e., above-average county wage) workers tend to be less applicable. When securing discretionary incentive packages — which are often the most generous but require approval — it is critical to remember the common requirement that the incentive be negotiated prior to committing to or announcing your final location decision. Timing and regular communication with the state EDO matter greatly when seeking discretionary incentive awards.

Regulatory Climate

The local regulatory climate is best assessed by talking to manufacturers in the community. A key consideration for most manufacturers, regulatory concerns focus first on permitting required to expedite building construction or improvement. Once the plant is operational, the key regulatory concerns turn to environmental, transportation, or labor regulation.

The local EDO can often help arrange for the company or its consultant to confidentially interview manufacturers in the area. On several of our engagements, the manufacturing CEO considering the community participated in these interviews with the primary intent of exploring the regulatory landscape. In particular, the CEOs wanted to discuss with their counterparts strategies for dealing with the specific regulators with whom they expect to have the most interaction.

Final Thoughts

Every site will come with its own tradeoffs. Locations attractive to one advanced manufacturer are likely home to other advanced manufacturers. For example, a location with very low energy costs has probably attracted other energy-intensive manufacturers and, as a result, local labor market conditions are tight. On the other hand, a community with a great property still available probably has other issues — perhaps unfavorable tax policy, high energy costs, or poor labor relations. A successful site selection engagement will uncover and quantify these tradeoffs, identify specific strategies for your company to mitigate local challenges, and position your advanced manufacturing company for success at your new U.S. location.