The February 24 Executive Order, which looks to review the vulnerabilities in U.S. supplies of critical technologies, metals, and pharmaceuticals, adds further urgency to fixing the disconnects. While it’s unlikely any laws will go into effect in the near term, the eventual resulting policy from the review could have long-term implications for U.S. businesses.

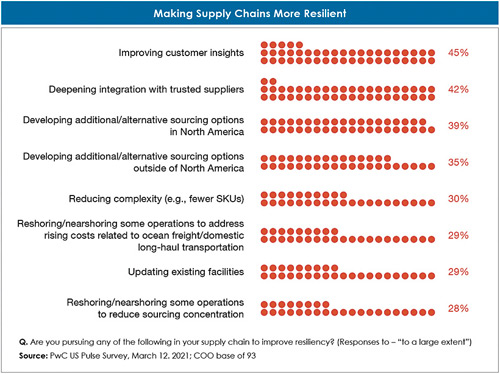

In a March 30 speech about the American Jobs Plan, President Biden included additional detail that his proposal would reward companies that invest at home. Yet, only 29 percent of company chief operating officers (COOs) responded they would consider reshoring or nearshoring some operations to address rising costs related to ocean freight/domestic long-haul transportation, and only 28 percent were looking at reshoring or nearshoring some operations to reduce sourcing concentration.

Nearly half of operations leaders surveyed in the recent PwC US Pulse Survey indicated that reducing supply chain disruptions is “very important.” President Biden is calling on Congress to invest $50 billion to create a new office at the Department of Commerce dedicated to monitoring domestic industrial capacity for critical goods and another $50 billion to invest in semiconductor manufacturing and research.

But until there is further clarity on how policy might take shape, moving manufacturing infrastructure is likely not in the cards for most companies just yet. Still, there are critical steps businesses can take in the near-term to prepare proactively for near- and long-term changes in policy.

Policymakers often don’t know the ins and outs of every business. Sharing your story with regulators and showing them how your supply chain operates can help frame future policy decisions and, significantly, can help deter policy missteps. Identify where jobs exist along your supply chain and how they could be reset to create more U.S. jobs. Also show what support may be needed to overcome the hurdles of reshoring capital investments. Thirty-one percent of operations leaders responded that they are looking to improve their organization’s resiliency through initiatives like expanding suppliers.

President Biden is calling on Congress to invest $50 billion to create a new office at the Department of Commerce dedicated to monitoring domestic industrial capacity for critical goods. Align your business with possible tax implications.

The relocation of people, processes, or technology could have significant tax implications. Pay attention to how income is adjusted between jurisdictions, which may further alter tax attributes, as well as potential tax exits, which could result from moving key profit-driving assets or functions out of the jurisdiction. Internal communication is often one of the biggest challenges within many companies; making sure the trade team is connected with supply, logistics, tax, finance, and planning takes coordinated effort but can reap significant rewards and avoid potential pitfalls, especially as taxing authorities around the world become more aggressive.

Develop and diversify strategic reserve capacity in suppliers.

It’s difficult to build up capacity with little notice, and therefore unforeseen complications like a global pandemic or a container ship running aground in a key shipping lane could easily result in shortages. Diversify the supplier base and eliminate single or concentrated sources of supply. Move toward multi-supplier and multi-geography supply strategies.

The relocation of people, processes, or technology could have significant tax implications. Identify potential threats.

From cybersecurity to climate change, there are a wide variety of threats that could disrupt a supply chain, but that can cause little impact with the right preparation. Evaluate potential pain points — no matter how far-fetched. Many companies still have room for improvement in these areas; only 40 percent of COOs said they were advancing environmental, social, and governance (ESG) strategies and only 34 percent said they would improve analytical capabilities.

President Biden has made it clear that creating American jobs, bringing industry back to the U.S., securing digital infrastructure, and tackling climate change are major initiatives for his administration. Furthermore, board members are increasingly tasking management with uncovering supply chain dependencies. Taking an inventory of how each of these issues impacts your broader supply chain will go far in preparing your organization for the inevitable policy changes coming in this space.