While it may seem that approaches to ensuring food safety and sanitary design would not change significantly over time, there are several recent factors impacting decision-makers. Consumers’ preferences for minimally processed foods with nontraditional savory and exotic ingredients influence facility and process design. Non-GMO, allergen-free, local, and other trends impact recipes and ingredient supply chains. After preparation and cooking, material flow paths, room separations, and HVAC must be carefully addressed to ensure no recontamination or adulteration is possible. Redundant dedicated processing equipment, restrictions on production schedules, and more complicated sanitation procedures may be required. It is now very common for food manufacturers to conclude that existing equipment cannot be adequately sanitized and must be replaced. Furthermore, after a certain point, the hurdles to ensuring food safety and implementing best practices in sanitary design are so great that a decision is made to retire a plant and build a new facility.

Sanitary Design: A Brief History

During the Reagan years, the U.S. Department of Agriculture (USDA) stopped approving construction drawings. Sanitary design responsibilities shifted to owners and operators. The Food and Drug Administration’s (FDA) cGMPs (current good manufacturing practices) were not as prescriptive or detailed as the USDA’s had been at that time. Kraft had the best standards for sanitary design of equipment and ran training courses for vendors and design firms. Buyers could specify “The Kraft Standards” as an option on many pieces of food processing equipment.

Around 2002–2004, the AMI (now the North American Meat Institute (NAMI) led two task forces which built on the designs promoted by Kraft and expanded the discussion to bring in best practices from the leading manufacturing and plant design firms. Updated in 2014, the equipment checklists are available on the NAMI website. The facility design guidelines are available from consultants and design firms as well as from Commercial Food Sanitation. Building on these efforts, the Grocery Manufacturers Association (GMA), the American Institute of Baking (ABI International), and other groups adjusted the approaches for low-moisture, produce, dairy, nut processing, and other sectors.

Standards, checklists, guidance documents, and certifications are also promoted by other groups. 3A and Pasteurized Milk Ordinance (PMO) standards are well established for the dairy industry. And 3A, American National Standards Institute (ANSI), and the National Science Foundation (NSF) develop standards for meat and poultry equipment. The European Hygienic Design Group (EHEDG) certifies equipment. ISO (International Organization for Standardization) is also active.

If existing equipment cannot be adequately sanitized and must be replaced, it’s not uncommon to retire a plant and build a new facility. Arguably, the greatest impact on food producers has been the requirements from retailers to their supply chains under the Global Food Safety Initiative (GFSI). In the United States, most common are certifications that meet this requirement awarded by Safe Quality Foods (SQF) and the British Retail Consortium (BRC).

After inadequate sanitation practices at the Peanut Corporation of America led to a 46-state outbreak of Salmonella poisoning — including nine deaths –— in 2009, the issues of food safety and sanitary facility design were elevated to a heated national debate. That led to the implementation of the Food and Drug Administration’s Food Safety Modernization Act (FSMA), signed into law in 2011.

The FSMA does not detail requirements for equipment or facility design. Rather, operators, primarily using Hazard Analysis and Critical Control Points (HACCP) and Hazard Analysis and Risk-Based Preventive Controls (HARPC) techniques, identify the required changes or investments. These can be numerous and vary widely as circumstances warrant. Captive boot programs, renovations to improve employee gowning and entrance vestibules, and new “CIP-able” equipment (i.e., equipment that can be cleaned in place) go a long way in meeting FSMA goals but are not directly required by the new rules.

Sanitary Facility Design Best Practices

The previously mentioned AMI principles are commonly the point of reference for new construction, remodeling, and renovation of food processing plants, and not just those in the meat and poultry industries. The principles are as follows:

- Distinct hygienic zones are established in the facility.

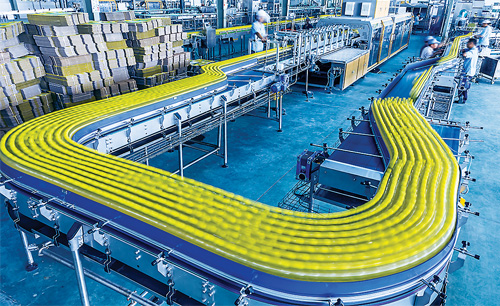

- The movement of personnel and materials flows is controlled to reduce hazards.

- Water accumulation is controlled inside the facility.

- Room temperature and humidity are controlled.

- Room airflow and room air quality are controlled.

- Site elements should facilitate sanitary conditions.

- The building envelope must facilitate sanitary conditions.

- Interior spatial design promotes sanitation.

- Building components and construction facilitate sanitary conditions.

- Utility systems are designed to prevent contamination.

- Sanitation is integrated into facility design.

- For most food plants that clean with water and sanitizers, floors must be designed for proper draining. Site grading must direct water away from buildings.

- HVAC systems must control humidity, temperature, airflows and quality, with strategies ranging from filtration to room-to-room pressure monitoring.

- Piping or ceilings in food processing areas must not be prone to condensation.

- Surfaces should be hard and nonporous and resistant to any chemicals that will be used to clean the facility.

- All connection points and joints must be sealed, without crevices in which dirt or microbes can accumulate.

- All building openings, including utility conduits, pipes, and ductwork, must resist entry by insects or rodents. Horizontal surfaces or ledges that hold dust should be avoided.

- All objects should be placed away from walls and elevated from floors to simplify cleaning.

- Adequate lighting, which is critical to maintaining a clean environment, must be provided.

While it’s possible to reduce the requirements for sanitary design to a concise, numbered list, actual decisions that will affect a plant’s performance can number in the hundreds — or more. A detailed process is, therefore, crucial when planning for food safety and sanitary design. Combined with the shorter timelines that are now common during construction projects, the result is a heightened demand for experienced designers and builders, as well as for new workflows and technologies that can support a more integrated approach to facility construction.

Traditional project delivery, in which responsibility is handed off from designer to engineer to operations team, does not support contemporary quality and safety standards. A structured preconstruction approach that solicits input from many stakeholders is more effective, allowing teams to make very specific decisions early in the planning process — right down to equipment selection and finish specifications — while improving project definition in terms of scope, schedule, and cost. Use of engineer-led design/build firms, which make a single firm responsible for the end-to-end construction process, is a fast and easy method for integrated design processes.

While the amount of information available to plant owners and operators has improved in recent years, it’s still not practical to assume that studying the available literature will be sufficient to optimize food safety and efficient operations. Forward-thinking food companies will use a variety of resources, including third-party consultants or other specialists, to ensure sanitary design success.