Making Sense of Today's Supply Chain Chaos

Manufacturing and logistics executives know uncertainty has always been part of global supply chains. Yet today’s volatility—influenced by dramatic swings in transportation costs, sudden geopolitical disruptions, shifting tariffs, climatological events, and significant energy shortages—is uniquely challenging. These are not theoretical concerns—they are concrete issues directly impacting supply chain companies' real estate strategies, location decisions, and ultimately their profitability.

Consider ocean freight costs. Container shipping rates have swung wildly from about $3,000 per container to peaks near $30,000, disrupting corporate budgets and forcing rapid adjustments to sourcing strategies. These unpredictable cost changes mean that a facility strategically located one year ago might suddenly become economically unviable the next. When logistics costs spike without warning, even the most efficient facilities can become financial burdens. Geopolitical events such as the Suez Canal blockade, the Ukraine conflict, and tensions in the Middle East have intensified these disruptions, injecting unpredictability into global supply chains and forcing executives to reconsider their long-term facility planning.

Tariffs, too, have played an outsized role in recent volatility. For example, when tariffs soared by 145 percent on goods from China, shipping activity slowed dramatically. Companies paused shipments and re-evaluated sourcing strategies. Then, when certain tariff enforcement windows were paused or adjusted, companies scrambled to front-load cargo ahead of potential changes, flooding ports with inventory and overwhelming distribution capacity. The reaction to trade policy shifts—first halting, then rushing to accelerate—underscores the unpredictability facing executives today.

Why Facility Needs Are Suddenly Hard to Predict

These abrupt changes illustrate a core challenge: demand signals are no longer consistent or easy to interpret. In addition to the aforementioned supply disruptions and risks, variability in those signals has become the norm. A spike in consumer demand may be fleeting, or it may represent lasting structural change—companies are no longer sure. This introduces real risk to network design and real estate strategy.

Companies are offloading excess space in one region while scrambling for it in another.

COVID-19 was a case in point. Many companies adopted a "just-in-case" approach, adding inventory and warehousing capacity in anticipation of ongoing disruptions. As conditions stabilized, many reverted rapidly to "just-in-time," releasing vast amounts of leased warehouse space back onto the market. That pendulum swing, driven by demand signal variability, has led to significant misalignments between supply and space utilization.

Subleasing activity, for example, has reached all-time highs. As of Q2 2025, 225.2 million square feet of sublease space was available nationwide—up 3.7 percent from the previous quarter and 25.3 percent year over year, according to Savills Research. Companies are simultaneously offloading excess space in one region while seeking space in another. It’s not just a mismatch of supply and demand—it’s a reflection of how variable demand signals and supply chain risks are influencing strategic decisions.

Real Estate Market Impacts You Can’t Ignore

The real estate market has mirrored supply chain instability. Industrial real estate absorption had been growing steadily in the years leading up to the pandemic, driven by the rise of e-commerce. It then surged during and after lockdowns, as increased consumer spending on household goods combined with supply chain bottlenecks to create a perfect storm. The sudden influx of demand resulted in aggressive construction of industrial buildings, leading to overcapacity. Construction starts peaked in 2022, but many of those facilities came online in late 2023 and early 2024, just as demand began to taper off.

Markets such as Phoenix and Atlanta now face high vacancy rates due to this oversupply, while markets anchored by smaller, localized industrial buildings or very large fulfillment centers remain resilient. Detroit, for example, has maintained a more stable market due to incremental, demand-driven growth. The I-85 corridor between Montgomery, Alabama, and Virginia absorbed over 70 million square feet annually during the peak. But that pace is no longer sustainable, and vacancy rates are rising.

Power is becoming a filter, not a footnote, in location decisions.

These fluctuations highlight a critical need for executives to reassess and recalibrate their real estate strategies, focusing on precise market timing and flexibility in lease structures Generally speaking, mid-size buildings (200,000 - 750,000 square feet) appear especially vulnerable in the current climate due to oversupply. Smaller buildings continue to serve trades, service providers, and last-mile delivery well, and have seen limited recent development. Meanwhile, the supply-demand dynamics for massive e-commerce hubs—often purpose-built for specific users—remains relatively strong. Size matters, but so does specialization.

Where Companies Are Actually Moving—and Why

The current uncertainty has led companies to prefer shorter-term, tactical real estate moves rather than strategic, long-term commitments. An increasing number of firms are turning to third-party logistics providers (3PLs) for their warehousing needs. This approach allows companies to scale operations up or down quickly without significant capital expenditure or long-term obligations, providing much-needed flexibility during uncertain times.

225.2M

Similarly, foreign trade zones and bonded warehouses have become increasingly attractive amid tariff volatility. These facilities allow companies to defer tariff payments until products leave the warehouse, enabling more strategic timing of market entry and tariff management. Bonded warehousing is not a long-term solution, but it is a valuable mitigation strategy in the current policy environment. Many companies are using this tool to buy time while they assess whether new tariffs will stick or be reversed after election cycles.

Additionally, the trend toward nearshoring is gaining momentum, with Mexico emerging as a favored alternative to China due to lower labor costs and proximity to the U.S. market. Cross-border trade with Mexico, particularly through Texas, has surged dramatically, necessitating increased warehouse and logistics capacity along these routes. The inland port of Laredo now handles more freight than many coastal ports, and demand for industrial real estate in border towns has skyrocketed. Site selectors evaluating locations along southern supply chains are increasingly prioritizing truck access and intermodal infrastructure over traditional port access. However, the 2026 renegotiation of the USMCA looms.

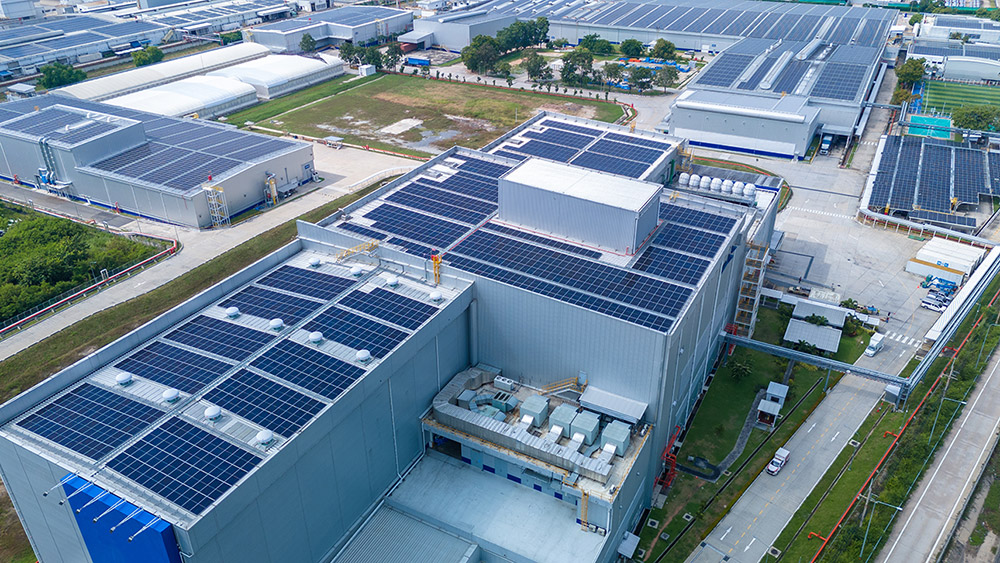

Power Availability—The Hidden Factor

Amid all these supply chain and real estate considerations, one critical but often overlooked factor is rapidly emerging as a decisive site-selection criterion: power availability.

The best real estate strategy isn’t the fastest—it’s the most adaptable.

The growth of energy-intensive industries—electric vehicles, data centers, artificial intelligence facilities—has created staggering demand for electricity. In recent years, companies have queued up for about 2.6 terawatts of new power capacity—more than double the existing U.S. generation capacity. This means that even if a site has ideal logistics, labor, and incentives, a lack of power can disqualify it. Companies are increasingly walking away from attractive deals simply because there isn’t enough electricity available—or it will take too long to bring it online.

Power availability is becoming a filter, not a footnote. Some companies now begin the site selection process by asking utilities for substation and transmission capacity before any other criteria are reviewed. In power-constrained markets like Northern Virginia, Phoenix, and parts of California, that early disqualification is becoming more common.

Strategic Adaptation in a Shifting Landscape

Rather than react to disruptions after the fact, executives are beginning to adapt in more forward-looking ways. Some are investing in advanced network modeling and digital twins to simulate future supply chain scenarios and risks. These tools enable organizations to evaluate their current footprint, identify potential bottlenecks, and visualize alternative configurations that optimize speed, resilience, and cost. One client we worked with discovered through digital modeling that their redundant regional distribution network was adding significant (i.e. >40%) transportation costs without improving customer service. By realigning responsibilities among sites and adjusting service areas, they improved efficiency and freed up capital.

2.6

Others are leaning into automation to mitigate workforce uncertainty and handle volume fluctuations more effectively. Unlike labor, which can be difficult to scale up or down quickly, automation infrastructure can be adjusted to meet demand in real time. Investing in automation also allows companies to maintain operations during labor shortages or policy-driven wage spikes. For some of our clients, automation is not just a productivity play—it’s a strategic hedge against volatility.

Finally, companies are making more strategic decisions about location. Instead of pursuing tax incentives or labor alone, many are looking for regions that offer long-term sustainability. That includes rail-served industrial parks, inland ports, and multi-modal hubs. While rail isn't ideal for all businesses—some see it as too slow or unpredictable—it remains essential for heavy manufacturing sectors such as plastics and metals. Those that rely on bulk raw materials are increasingly seeking rail-connected sites, despite concerns about service predictability.

Becoming Flexible, Not Reactive

Today's heightened volatility underscores a vital truth: companies must evolve beyond simply reacting to disruptions. Those that embrace flexibility, proactively adjust their real estate strategies, and integrate advanced supply chain insights into facility planning will thrive.

Adaptability is no longer a competitive advantage—it is a requirement. Businesses prepared to pivot rapidly and strategically will gain significant operational stability and resilience. The past few years have shown us that supply chains are no longer invisible back-end systems. They are strategic assets, and how companies manage their physical footprint—where they locate, how they lease, how they mitigate risks, and how they plan for growth—will define who wins the next decade.

The key to navigating the current environment isn't brute strength or mere intelligence—it’s flexibility. As we often tell our clients, the companies that succeed are not the biggest or the fastest. They are the ones most willing to evolve. And in this market, nothing is evolving faster than the intersection of supply chain and industrial real estate.